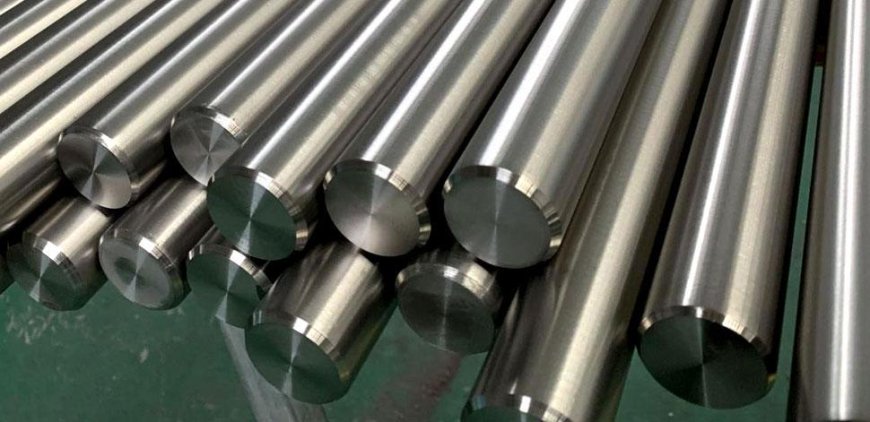

What are Hastelloy Round Bars? A Detailed Guide

Hastelloy round bars are essential components for high-performance applications. Their outstanding corrosion resistance makes them especially valuable in industries like oil refining and power generation.

Machinability and weldability of this alloy is also quite good; however, when working with it it is imperative to use appropriate tools and techniques.

What is Hastelloy used for?

Hastelloy alloys, like other nickel superalloys, are highly corrosion-resistant and easy to weld, making them popular choices in chemical processing, aerospace, oil & gas, nuclear power and power industries.

Hastelloy stands out from other nickel-based alloys with its distinctive composition: an amalgamation of metals and nonmetals such as nickel (Ni), chromium (Cr), molybdenum (Mo) and iron (Fe). This combination provides excellent corrosion resistance in moderate to severe environments.

Selecting an appropriate Hastelloy grade for your project is of critical importance, as its suitability will ultimately dictate what kind of working environment and lifespan it can withstand. Consider factors like its oxidizing or reducing properties as well as whether chlorine exists; chlorine can lead to pitting and cracking effects in Hastelloy grades like C-276 that offer excellent resistance.

What is the hardness of Hastelloy C276 round bar?

Hastelloy C276 round bar is an exceptionally corrosion resistant alloy used across numerous industries. Composed primarily of nickel with additional elements including chromium, molybdenum and tungsten content - making it suitable for use in petrochemical, aerospace and oil and gas applications as it resists pitting corrosion, crevice corrosion and chlorine stress corrosion cracking cracking applications.

Hastelloy C276 boasts exceptional corrosion resistance, along with exceptional machinability. This means it can easily be cut, machined and welded; plus it features formability and ductility - though due to lower thermal conductivity than steel it should be used with appropriate support structures and expansion joints to avoid cracking.

Which is better alloy 20 or Hastelloy?

If you need corrosion resistant materials, there are various alloys to consider. Alloy 20 is one popular choice; Hastelloy also provides unique benefits depending on where it will be used.

Alloy 20 is an excellent material choice for chemical processing plants that need resistance to sulfuric acid, with higher nickel and molybdenum content than Hastelloy for superior wear resistance and durability.

Hastelloy C276 is an ideal material for environments requiring corrosion resistance against chlorine and other halides. Composed of nickel, chromium and molybdenum in an optimal balance for corrosion protection in chloride environments; its excellent pitting and crevice corrosion resistance provides superior pitting/crevice corrosion resistance as well as stress corrosion cracking resistance as well as outstanding creep strength at higher temperatures.

What is the ASTM standard for Hastelloy?

Hastelloy is a super alloy made of nickel-molybdenum-chromium with great corrosion resistance in various environments. It excels in resistance against pitting and crevice corrosion in chloride environments as well as having excellent stress corrosion cracking resistance in both reducing and oxidizing conditions.

Nickel content lends it great resistance against reducing environments, while molybdenum and chromium help protect it against oxidizing environments. Furthermore, its low carbon content minimizes carbide precipitation during welding processes to maintain corrosion resistance even in weld heat-affected zones in an as-welded condition.

HT PIPE manufactures and exports Hastelloy Round Bar, Hollow Bar, Square Bar, Hex Bars and Rods to suit customer specifications and ASTM B472. Our products are widely sought after within oil & gas, power generation and chemical processing industries.

Why to use Hastelloy Round Bars?

Hastelloy alloys provide exceptional resistance to corrosion across a wide array of environments, such as oil and gas, aerospace, pharmaceuticals and chemical processing plants where these alloys may come into contact with aggressive acids and high temperatures.

Nickel-based alloys are also highly sought-after by oil and gas industries due to their resistance to sea water environments, making them suitable for offshore drilling applications as well as seawater cooling systems with cooling capabilities that resist pitting and crevice corrosion.

Hastelloy round bars by kanakratna steelage are easy to work with and can be manufactured using standard fabrication techniques. Furthermore, their formability and ductility make them suitable for challenging applications; additionally they boast excellent weldability with inert tungsten gas welding (TIG).

![Top 9 Real Estate Mobile App Developers in Riyadh, Saudi Arabia [2025 Edition]](https://www.biphoo.uk/uploads/images/202507/image_430x256_6879d0d524335.jpg)