The Role of HRPO Steel in Agricultural Equipment Manufacturing

Discover how HRPO (Hot Rolled Pickled and Oiled) steel plays a crucial role in agricultural equipment manufacturing by offering enhanced corrosion resistance, weldability, and cost-effective durability for farm machinery.

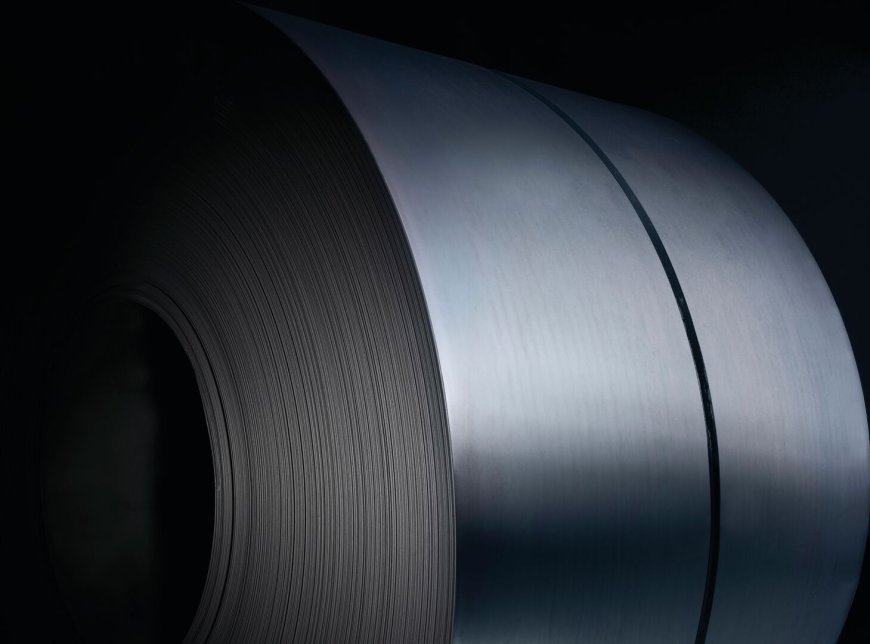

In the agricultural sector, equipment durability and performance are crucial for productivity and long-term reliability. As farming becomes more mechanized, the materials used to manufacture agricultural tools and machinery must meet stringent demands for strength, corrosion resistance, and workability. One material that stands out in this context is HRPO (Hot Rolled Pickled and Oiled) steel. Known for its clean surface, excellent formability, and enhanced corrosion resistance compared to untreated hot-rolled steel, HRPO steel plays a vital role in manufacturing a wide range of agricultural equipment.

What Is HRPO Steel?

HRPO steel starts out as hot-rolled steel, which is produced at high temperatures and typically has a rough, scaly surface due to the formation of oxides. To make it more suitable for fabrication, it undergoes a pickling process, where it is cleaned with acid to remove the oxide scale. After pickling, the steel is coated with oil to prevent rust and preserve the clean surface. This final productHot Rolled Pickled and Oiled steeloffers many advantages over both untreated hot-rolled and cold-rolled steel in agricultural applications.

Why HRPO Steel Is Ideal for Agricultural Equipment

-

Improved Corrosion Resistance

Agricultural equipment is often exposed to harsh environmentsmoisture, soil, chemicals, and fertilizers. HRPO steels oiled finish provides a basic level of corrosion resistance, making it a better option than raw hot-rolled steel for outdoor use and prolonged exposure to weather conditions.

-

Better Weldability and Formability

HRPO steel retains the mechanical properties of hot-rolled steel but with a much cleaner surface. This makes it easier to weld and form into complex shapes, which is essential when manufacturing components like frames, chassis, supports, and panels for tractors, tillers, and harvesters.

-

Consistent Surface Finish

The pickling process results in a smooth, scale-free surface. This uniform finish improves the appearance of finished agricultural tools and makes painting or powder coating easier and more durable. A clean surface also reduces the risk of equipment failure caused by surface defects.

-

Cost-Effective Material

Compared to cold-rolled steel, HRPO sheet is more economical while still offering many of the same benefits needed for agricultural applications. This makes it a preferred material for manufacturers aiming to balance performance with cost-efficiency.

Common Agricultural Applications of HRPO Steel

-

Tractor Frames and Structural Components

The high strength and weldability of HRPO sheets make them ideal for the structural parts of tractors and other heavy equipment.

-

Harvester Blades and Covers

HRPOs clean finish allows for easy shaping and surface treatment, making it suitable for covers, guards, and even cutting blade supports.

-

Implements like Plows, Tillers, and Seeders

These tools require tough, formable steel that can withstand repeated mechanical stress and contact with soil. HRPO fits the bill due to its balance of durability and ease of fabrication.

-

Storage Bins and Feed Equipment

HRPOs resistance to corrosion and its compatibility with protective coatings make it a smart choice for fabricating feed hoppers, silos, and grain handling systems.

Conclusion

The agricultural industry demands materials that can endure rigorous use, weather extremes, and corrosive environments. HRPO steel has proven itself to be a reliable and efficient material in this sector due to its superior surface finish, enhanced corrosion resistance, and ease of fabrication. As the demand for robust, long-lasting agricultural machinery continues to grow, HRPO steel will remain a go-to choice for manufacturers aiming to deliver performance, durability, and value.

![Top 9 Real Estate Mobile App Developers in Riyadh, Saudi Arabia [2025 Edition]](https://www.biphoo.uk/uploads/images/202507/image_430x256_6879d0d524335.jpg)